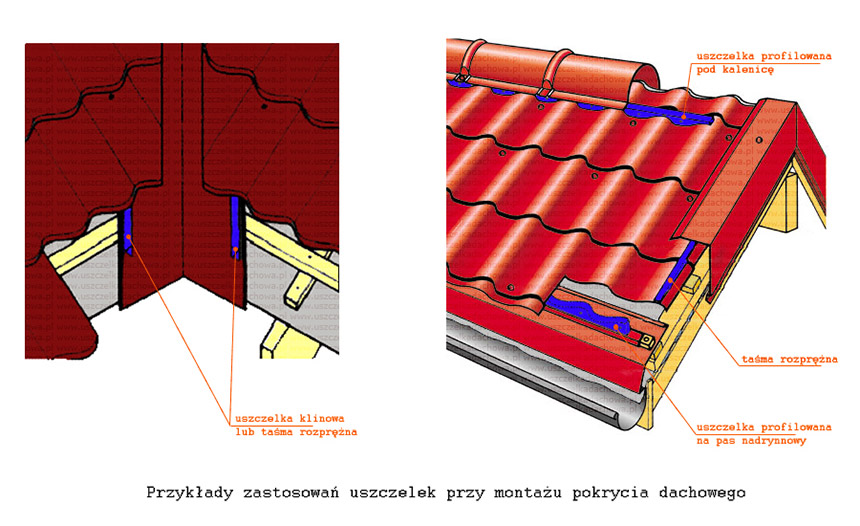

SEAL UNDER THE RIDGE TILE AND GUTTER STRIP

Self-adhesive wedge seals made of technical or filter foam. They prevent leaves, dust, birds from getting under the roof covering, they also prevent snow drifts.

Flexible polyurethane foam /PUR/- highly flexible with a cross section in the shape of a right triangle, unilaterally equipped with a glue film protected with silicone paper.

Application:

- sealing of valley gutters

- sealing of roof window collars

- sealing of the ridge on roof slants

- brick,

- bronze,

- anthracite.

- 1000x50x30mm

- 1000x60x30mm

- 1000x70x30mm

Standard dimensions

| Type of raw material | Apparentdensity PN-EN ISO845 |

Air permeability | Color | Seal height [mm] |

| Polyurethane foam | 18-26 | Very high | Anthracite, Brick, Bronze |

50, 60, 70 |

| Polyurethane foam Flame retardant | 23-26 | Very high | Light gray | 50, 60, 70 |

| Filter foam | 25-35 | Very high | Dark gray, Black |

50, 60, 70 |

Wedge seal with a filter:

Self-adhesive, made of filter foam of filtren type. It is a reticulated polyurethane foam - a foam that has a completely open cellular structure.

Application:

It is most often used for ridge, valley gutter, gutter drip and side fittings. It protects against pollutants like dust, water, snow, leaves.

Wedge expansion seal:

Self-adhesive wedge seal made of a flexible polyurethane foam saturated with a suspension of modified acrylic. Acrylic impregnant definitely improves usability qualities of polyurethane seals, increasing their resistance to aging.

Application:

- roof sealing: sealing of slants, valley gutters and roof ridges,

- sealing of roof window collars,

- fillingin gaps in roof, wooden, concrete structures and others.

It ensures excellent protection of gaps against the impact of atmospheric factors.

Very high resistance to chemical compounds and UV radiation.